project value

hours worked on site

services at Prism

fabricated bracket assemblies

Addressing climate change and the transition to low carbon energy is a defining priority for the 21st century. At Drax Power Station in Yorkshire, an expert team from SES Engineering Services (SES) helped realise that vision by supporting the UK’s largest ever coal to sustainable biomass conversion.

Typically supplying 7–8% of the UK’s electricity, upgrading three of Drax’s six generators has shaped the future of low carbon energy generation. With almost half the power station now running on 100% sustainably-sourced biomass, these world-class facilities are enabling Drax to achieve their business goals by generating up to 1,260 megawatts of renewable electricity per day, making it one of Europe’s largest producers of renewable power.

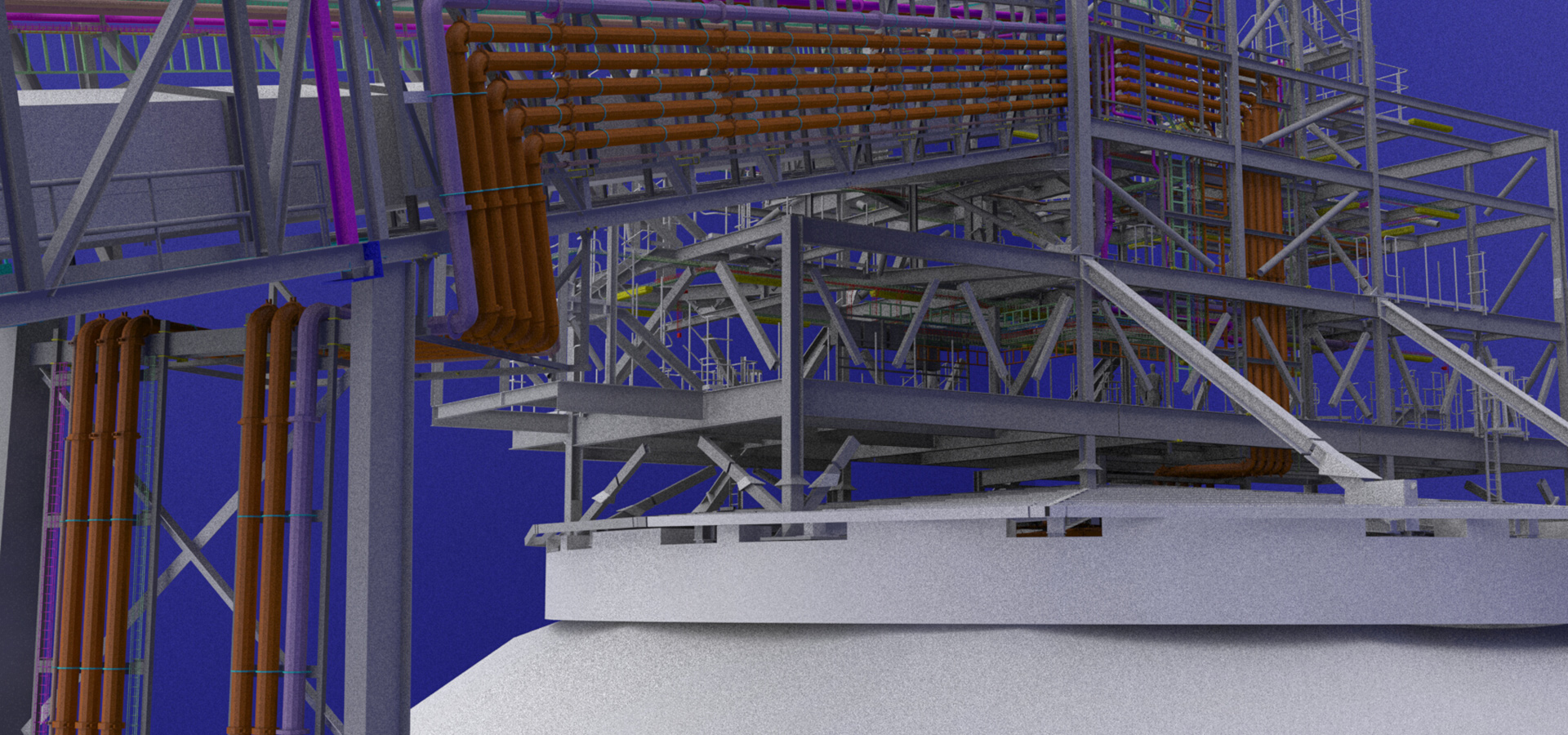

Due to the fast track nature of the project, the prime directive was to focus on innovative solutions that would deliver a quality product to the client in an incredibly short time-frame. Complex solutions were delivered collaboratively in this challenging live environment which included the creation of four extensive biomass storage domes – enabling capacity for an unprecedented 450,000m³ of biomass storage.

By prefabricating 35% of all services on the project at Prism, we were able to maintain the fast track programme, whilst greatly reducing the inherent risks of working at height and in a live power station environment. A staggering circa 3.8m man hours were worked on site to deliver this revolutionary project.

Through technical and delivery excellence, we provided the client with a world-class installation; delivering quality in offsite fabrication, BIM modelling, design, commissioning and complex technical engineering.

“As a UK-first, this project required the collective expertise only a built environment specialist could provide. Collaboratively, we’ve produced a feat of construction and engineering, the like of which this country has never seen, and one that will provide a long-term legacy for the UK’s renewables industry.”

Other Case Studies

SeAH Wind Monopile Factory

Due to complete in 2025, SeAH Wind’s giant 40-metre-tall, 800m long monopile factory will be the largest of its kind in the world.

Teesside Energy Centre

SES Engineering Services (SES) was appointed to design, install and commission the mechanical, electrical and plumbing (MEP) services on Teesside Energy Centre which was constructed by a consortium between Lagan Construction and Babcock & Wilcox Vølund (BWV).

Tinbergen Plantroom & CTL Building

SES Engineering Services (SES) completes enabling works to deliver £201.8m Life and Mind Building at University of Oxford