GSK has had a presence in Barnard Castle since the 1940s and since that time it has invested across its site expanding facilities to ensure it remains at the forefront of the pharmaceutical sector.

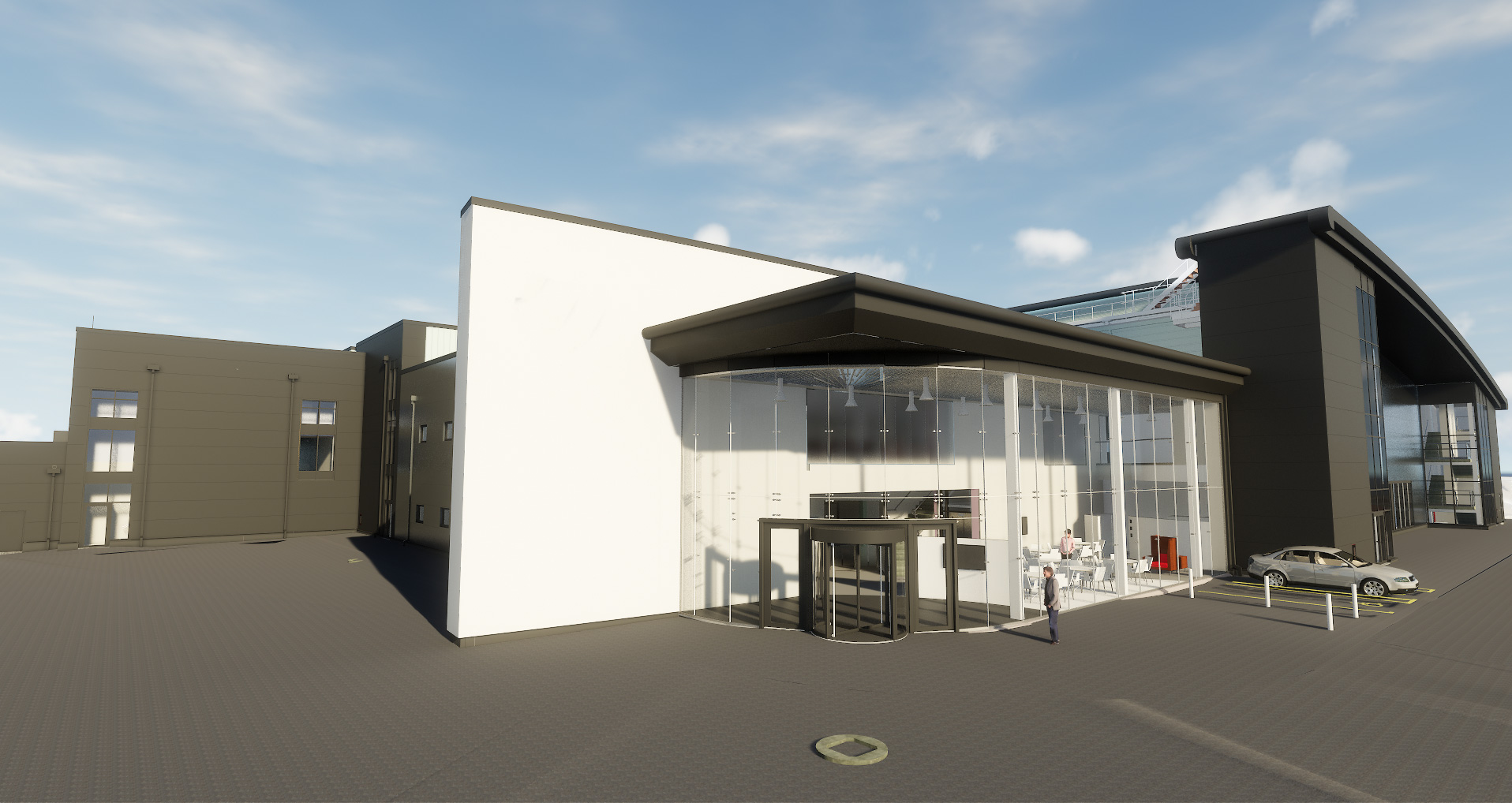

The new 11,500 sqm Q Block aseptic facility will allow GSK to add further to its broad range of products for HIV, respiratory and oncology treatment.

As can be expected of a pharmaceutical manufacturer, GSK works to the highest standards. These exacting standards and the need to guarantee quality and maintain tight control over the build process and schedule, along with the manufacturer’s desire to be able to replicate the building anywhere in the world, were key drivers in choosing offsite as the central construction method and which led to SES’ direct appointment with GSK.

Now on site, SES will work to a detailed schedule of works to install all mechanical and electrical (M&E) building services, ensuring that there is minimum disruption to the live manufacturing site.

Speaking about working on such a significantly important project for the global pharmaceutical market, and north east, Steve Joyce, Business Director North and Scotland, SES said:

“GSK is a forward-thinking company which identified and appreciated the importance of getting SES onboard at the earliest opportunity.

“This early engagement coupled with our BIM Level 2 experience and bespoke offsite capability, via our offsite manufacturing facility, Prism, allowed us to influence the M&E design at the outset of the project. As a result, a significant 60 percent of the MEP services will be produced offsite which meets a key target of GSK’s brief to replicate the building elsewhere in the world.

“I believe Q Block is an excellent example of offsite construction being used to best effect and I am delighted that SES has made such a positive contribution to the scheme.”

Commenting on the innovative project, Colin Driver, Project Manager, GSK said:

“This is an exciting phase in the ongoing development of our Barnard Castle manufacturing facility. The investment in biopharmaceuticals is critical to the future of pharmaceuticals and this is a flagship project for global investment.

“The idea is to replicate the design globally on secondary sites, building in the flexibility within individual modules, but also future-proofing the design for at least 10-20 years without the risk of drug regulatory impact, hence reducing future design costs. I believe this can only be achieved using offsite technology.”

Further to the M&E services benefiting from offsite technology, 40% of the building’s shell (including precast units, wall systems, steel framework and 95% of a 2.5Ksqm clean room will be created offsite.

It is anticipated that Q Block will complete in November 2019.

Related News

The case for a direct labour force post-Brexit

Jason Knights, Managing Director, SES writes that with an uncertain post-Brexit environment in our futures, firms should “rely less on contract workers and instead invest in maintaining a direct labour force.”

Trio of appointments as SES Engineering Services strengthens London and South East senior team

Leading national engineering specialist, SES Engineering Services (SES), is strengthening its leadership team in the London and South East region with the appointment of two new Operations Directors and a Regional Commercial Manager.

SES Engineering Services strengthens Midlands and South West regional senior team

Leading national engineering specialist, SES Engineering Services (SES), is strengthening its presence in the Midlands and South West region with the appointment of new Bid Manager, Ashley Rabone.